How to Remove Red Threadlocker

Removing LOCTITE® red threadlocker can be difficult, and it’s a common vehicle maintenance question. While the strength of our red threadlockers is formidable, and meant to be a permanent assembly method, don’t believe the myths: red threadlocker can be disassembled with the right technique.

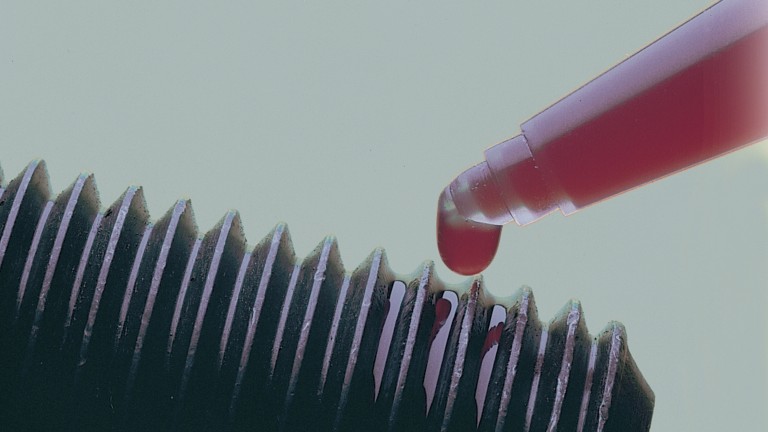

The process of knowing how to remove red threadlocker is a little different than for other threadlockers. The key is to apply localized heat greater than 250°C (550° F). Then, once the threaded assembly is hot, the bolt can be unthreaded. Without applying heat to the assembly, some bolts threaded into tapped holes risk breaking.

The ideal placement of red threadlockers is on bolts ranging from 1/4″ to 3/4″ diameter for some of the following areas:

- Bearing caps

- Motor mounts

- Suspension bolts

- Heavy duty equipment area

Commonly Asked Questions:

Below are some of the common ask questions we receive from customers about how to best remove the red threadlocker:

What will dissolve red LOCTITE®?

LOCTITE® SF 790 Chisel Paint Stripper or LOCTITE® SF 7601 Equipment Flushing Solvent can be used to soften cured red LOCTITE®. Mechanical abrasion will also be needed to assist with the removal.